- GST No. 24APBPS1066E2Z6

- Send SMS

- Send Email

| Business Type | Manufacturer |

| Material | Metal |

| Surface | Polished |

Details

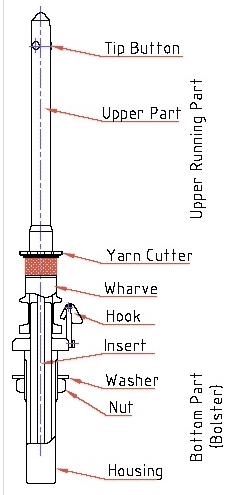

- Parts (1) to (4) are assembled together and this assembly is known as Bottom Part or Bolster.

- Parts (5) to (10) are assembled together and this assembly is known as Upper Running Part (URP).

- When both these parts are assembled together it makes the Complete Spinning Spindle.

- Each critical component manufactured like Bottom Blade, Wharye, Upper Blade and Bolster has an individual line of manufacture. At the end of manufacture it goes to the Assembly Department to be assembled as a complete Spinning Spindle.

- Each stage of component manufacture has its indiyidual guality checks, yerticality checks, etc., and on assembly final check and tests are carried out for yibration, eccentricity etc.

- We make 'SPINDLES' since 1995.So, long and rich experience in manufacturing 'SPINDLES'

- Spindle components are processed on CNC Lathe and CNC Grinding machines for consistent accuracy.

- If required "Hard-Chrome Plating" is done on shaft to prevent rust, & premature wron-out.

- Spindles are dynamically balanced on 'Two-Plane' soft bearing balancing machine.

- With our spindle we use Germany make "KEMAN" Brand HD-44, HD-55, HD-66, HD-68 & HD-77 Bolsters.

- Spindles are supplied with Bolsters fitted with Customised designed Brake.

Features

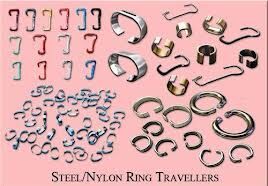

- Bolster

- Insert

- Nut

- Washer

- Bottom Blade

- Upper Blade

- Wharve

- Auto Hook

- Tip Button

- Spring

Spindles are manufactured suitable for replacement in major brand of D.T.Machines

- Teijin-Seiki

- Barmag

- Rieter

- Saurrer-Allma

- Ishikawa

Our spindles are also used in a O.E. by Indian Doubler & Twister machine manufacturer for Ropes, Twines, Fishnet yarn etc.

Graph

Looking for "Textile Spindle" ?

Piece